World Controls is an exclusive dealer for Reer S.p.A. who is one of the main manufacturers of optoelectronic safety devices for the prevention of accidents in machines and hazardous areas being leader in the palletizing market.

The optoelectronic safety devices (Safety light curtains or Safety light curtains) are the first choice to achieve maximum productivity of machinery and plants. Unlike fixed physical barriers such as screens and gates, these devices do not limit the space for handling and transporting materials in the factory, and provide a better overview of the machines for supervision and monitoring by the operators, not to mention the fact that they can be remotely supervised.

Reer S.p.A.’s wide range of products covers all the requirements for the protection of danger points, access and danger zones in the industrial sector, let’s take a look at its main products:

Reer Safety Light Curtains:

Safety light curtains, commonly referred to as safety light curtains, are used for applications in which danger points and danger zones must be reliably and economically protected. Regardless of the variant, they have various machine functions integrated or can be selected via safe control solutions. The Reer range encompasses small, compact designs or extremely robust and rugged variants for special environments up to the highest safety level.

Reer multibeam safety light barriers:

Multi-beam safety light barriers are non-contact protective devices with two or more light beams. If one or more of the light beams is interrupted, a shutdown signal is sent to the machine to interrupt its operation immediately to assess the potentially hazardous condition for operators and plant personnel. A system consists of a transmitter and a receiver. In active and passive systems the transmitter and receiver are located in the same housing and a deflector unit is responsible for deflecting the light beam.

Reer single beam safety light curtain:

Reer single beam safety light curtains consist of self-monitoring transmitters and receivers or testable transmitters and receivers in combination with an evaluation unit or Safety Relay (Safety Relay Module). These safety devices are characterized by their large range and the variety of shapes and arrangements in which they can be placed in the process. They correspond to type 2 or type 4 according to EN 61496 and according to EN ISO 13849. Typical applications include robots, machines and machining centers, palletizing systems, vertical warehouses or transfer lines.

Reer Safety Laser Scanners:

Reer safety laser scanners offer the right cost-effective package for every mobile or fixed application or can be used to secure an area or monitor access. Like optical radar, these compact systems scan their surroundings and measure distances according to the principle of light propagation time measurement. Thanks to the integrated rotating mirror, a two-dimensional scanning of protected areas with free definition and difficult configurations is created.

Reer safety encoders:

Reer safety encoders facilitate the implementation of safety functions and thus the safe and efficient operation of machines.

Encoders for functional safety provide information on position, angle and revolutions, which focuses especially on mechanical and electrical safety. In combination with safe control solutions.

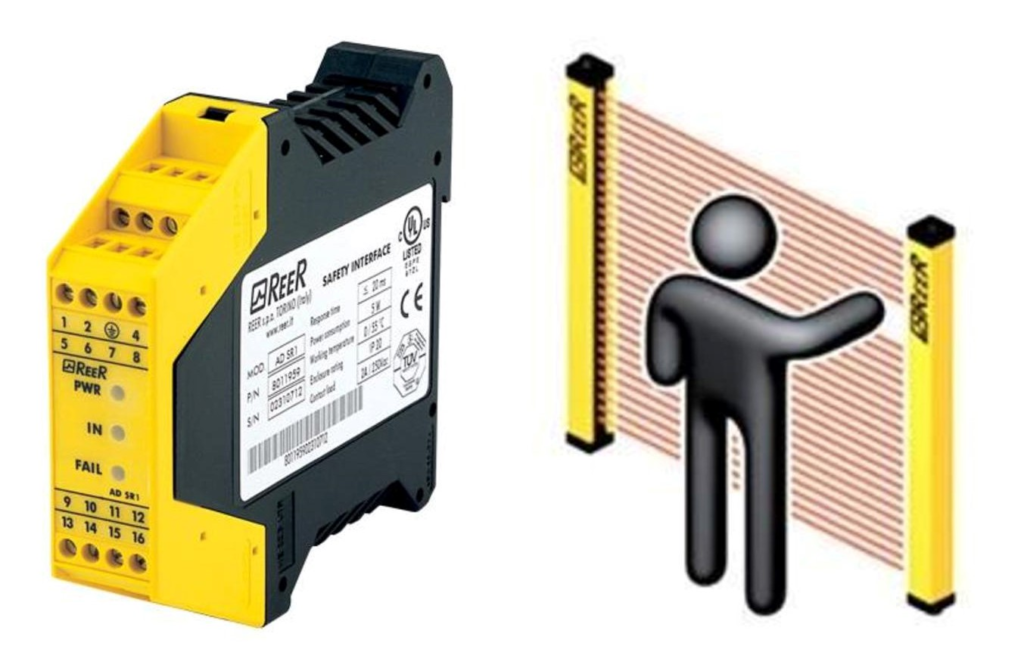

Reer safety relays:

Any safety element such as an emergency stop button, a light curtain, a pull switch or a safety laser scanner with PNP outputs can be connected to a safety relay for monitoring. Safety relays are thus the ideal devices for flexible and cost-effective integration into machines.

Reer Programmable Safety Controllers:

Reer S.p.A. offers a flexible solution to realize intelligent machine design. Mosaic safety controllers are a modular hardware platform, are easy to operate and program and can be easily integrated with all existing safety controller components. This line of programmable controllers features a compact design for a wide range of applications.

The Reer Mosaic series can control and supervise at the same time and in a single product, a large number of emergency stops, safety light curtains, magnetic sensors, magnetic and mechanical safety microswitches, with the possibility to create complex designs and safety conditions using logical operations and safety functions, programmed by means of user-friendly and intuitive software.